Maintenance professionals often report the biggest problems with their tribology program are over-greasing, under-greasing, wrong grease, and sometimes no grease at all. Over-greasing causes high temperatures and results in shedding of oil from grease.

Under-greasing causes inadequate lubricant delivery. The wrong grease in a bearing also has the same effect. It doesn’t properly deliver oil to the loaded rollers. All these result in lubricant-starved bearings.

These problems (over-greasing, under-greasing, wrong grease, and no grease at all) cause increased energy loss due to friction. This energy shows up as mechanical energy (ultrasonic) and thermal energy (heat).

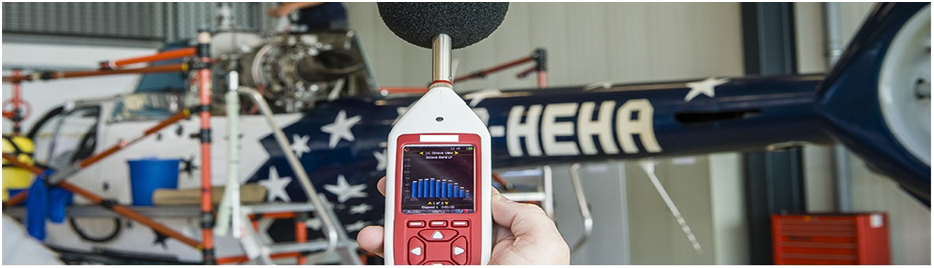

A noise survey takes noise measurements throughout an entire plant or section to

identify noisy areas. Noise surveys provide very useful information which enables us to identify:

We @ Rototech, can provide the below services in acoustic field.