Vibration Analysis

Vibration Analysis is the heart of any Condition Monitoring Program. Vibration analysis is like giving your equipment a check up from the doctor. Vibration is the only tool in a predictive maintenance toolbox that can accurately detect equipment problems like imbalance, misalignment, eccentricity, resonance and looseness that lead to bearing failure. In much the same way a stethoscope is placed on you by a doctor; placing a sensor on the bearings of a piece of equipment like a pump or motor can provide an understanding of its operating condition.

Vibration Analysis is a predictive maintenance method which allows early problem detection in rotating machinery, such as: gearboxes, fans, shafts, motors, compressors, pumps, mixers, driers – in fact, almost any type of active machinery. Vibration Analysis will identify component faults – such as defective bearings & misalignment – and enable you to take maintenance action before a failure in service brings your plant to a halt.

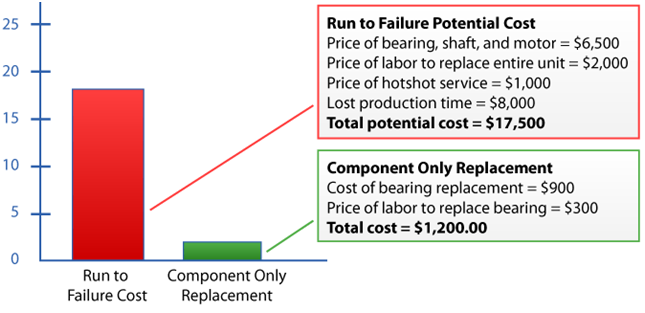

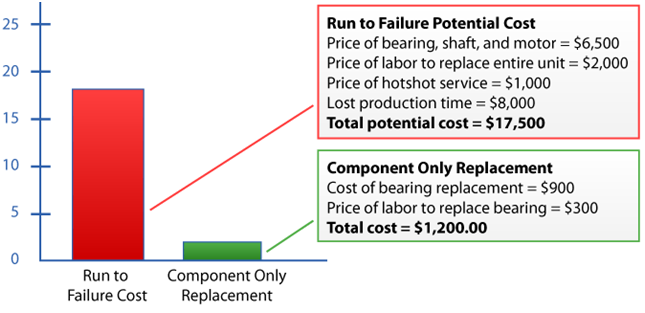

Cost Benefits of Vibration Analysis

The below chart indicates the cost benefit of implementing vibration analysis program in your company. Managing your assets without the vibration analysis program will cost you more than 15 times than the system with a strong predictive maintenance program.

Benefits of Vibration Analysis

- Reduces equipment costs

Instead of replacement of the entire piece of equipment due to critical failure, a repair is made prior to failure and cost is minimized to the price of the component and the labor needed for the repair.

- Reduces labor costs

When repairs are scheduled, the amount of time needed for repair is reduced because of a smaller number of component replacements instead of entire equipment replacement. Also, the frequency of repair for critical failure of equipment will be reduced and the amount of “critical callouts” will be greatly reduced.

- Reduces lost production time

Component only” replacement is scheduled along with production to take place during scheduled downtime. Unscheduled downtime may cost thousands of dollars per hour. A proactive maintenance department can head off critical failure downtime by scheduling repair during non-productive times.

- Increases safety

Predictive maintenance would allow potential problems to be fixed before failure occurs, which would create safer driving conditions for employees & customers, saves people life, assets, environment and company reputation.

- Increases revenue

With less maintenance on good components and quicker repair of faulty components, repairs can be more effectively handled, thereby reducing repair time.

- Increases efficiency of employee time

By identifying the precise repair task needed to correct deficiencies, as well as the parts, tools and support needed to correct the problem can dramatically increase effective “wrench time.”

![]()

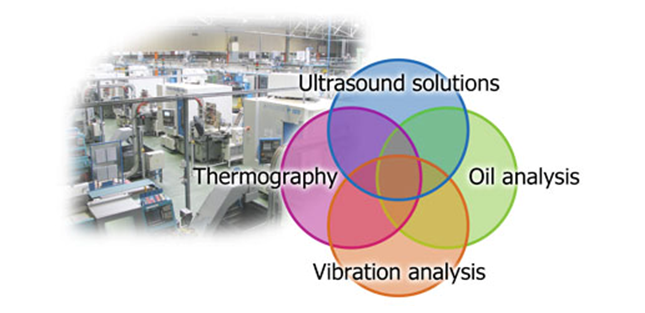

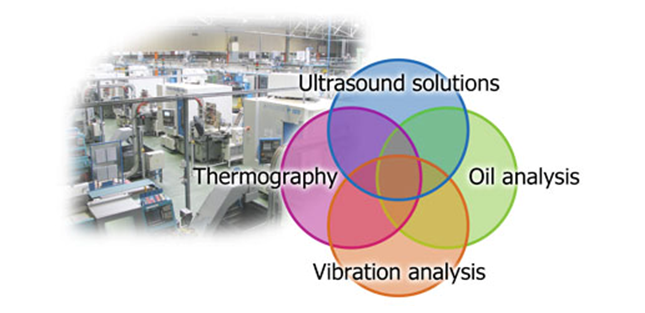

What we can do at Rototech?

Please contact us in case if your machine is vibrating beyond the acceptable limits. We will analyse your machine and provide the recommendations.

Below services are available @ Rototech 24×7 which is led by a team of specialist engineers.

- On call vibration analysis service will be provided for your assets with chronic vibration issues

- Provide Easy understandable reports with recommendations.

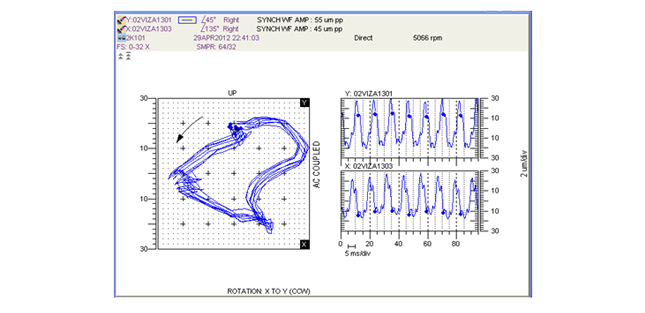

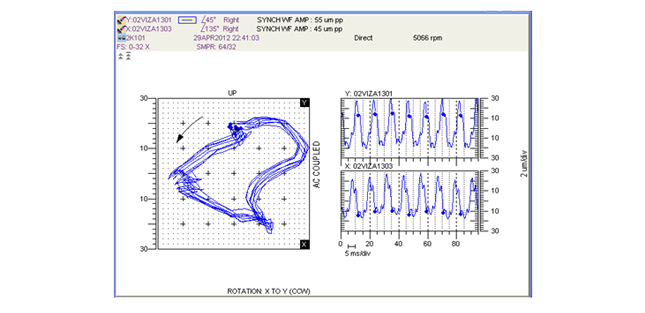

- Resonance, Phase measurements, Orbit analysis, bode plot analysis.

- Bump test, Coast-up/Coast- down measurements and transient data analysis.

- Ground and Building vibration data collection.

- Bearing analysis.

- Remote data analysis to support the customers.

- Human habitability measurements on board ships and vessels.

- Develop a predictive maintenance route, carry out vibration data collection & data analysis and provide the recommendations for the efficient management of your assets. Professional reports will be submitted upon completion of the project.

- Annual Predictive Maintenance Contract (AMC) is undertaken to maintain your assets.

- Contract based vibration

- Remote Assistance

- Human habitability measurements onboard ships and vessels

- Customised training can be provided to your management & staff to illustrate the cost benefits of implementing the predictive maintenance programs.

- We provide, Vibration analysis international level certification courses

We @ Rototech identify the root causes of your machinery vibration

- Unbalance – In the case of rotating equipment, the rotating mass must be equally balanced. An unbalance axis will create a centrifugal force which causes the machine to vibrate.

- Misalignment – A very common cause of vibration is due to misalignment of rotating shafts. Angular misalignment, parallel misalignment, soft foot and thermal expansions contribute to misalignment and high equipment vibrations.

- Wear – When components become overly worn they can cause vibration in machinery. Damaged areas of roller bearings or chipped gears can cause a machine to vibrate.

- Loose Connections – If a worn part does not become damaged over time it can easily become loose, thus causing vibration. The loose connections can become destructive very quickly, like loose mounts or anchors. Loose belts can cause fan vibrations.

- Auxiliary Equipment – The auxiliary equipment nearby main equipment can cause vibration on you equipment due to structural vibration transfer.

- Resonance – Resonance can cause high vibrations on your equipment. The piping and the structures connected to your equipment can cause vibrations if the natural frequency falls close to the equipment running speed. Cracks- Cracks on the equipment base and the other rotating parts can cause high vibration on your equipment.

![]()