Infrared thermography as a predictive maintenance inspection technique is a widely-recognized and effective non-destructive (NDT) testing tool used often to check electrical and mechanical systems, buildings, roofs and facilities. IR is also used to improve manufacturing processes and is utilized in R&D applications .

The use of infrared thermography (IRT) makes economic sense, regardless of the size and operation of your facility.

Over the years it has consistently shown unprecedented returns on investment.

Infrared is the only technology that can quickly see where excessive energy is being lost. Of course, overheating connections consume electricity, but usually nowhere near the magnitude of many industrial processes. Companies with boilers, furnaces, kilns and the like will reduce their energy costs by repairing and replacing missing and damaged insulation. Identification and removal of wet insulation in flat roofs will save heating and cooling costs. Losses around doors and windows can also save energy cost and prevent moisture from entering a building. Cryogenic liquids/gas leaks can also be quickly detected using both infrared and ultrasound technologies.

The more efficient a company is at producing a product, the higher the profit margins will be. This places a great demand on reliable utilities and reliable equipment. Whenever there is an interruption in one or both of these, efficiency drops and so does profits. In most cases the repairs for broken equipment is only a small percentage of the real loses a company feels; labor and products. As you are probably aware, these losses can vary from hundreds to tens of thousands of dollars per hour, and sometimes even higher. Using the predictive abilities of infrared inspections, your company will know when equipment is ready to fail so you will be given time to respond.

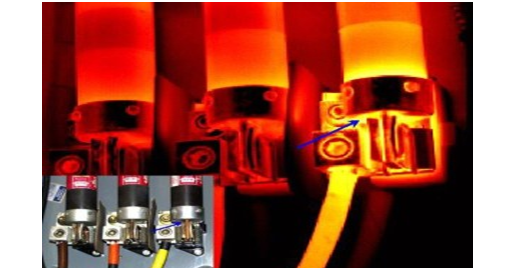

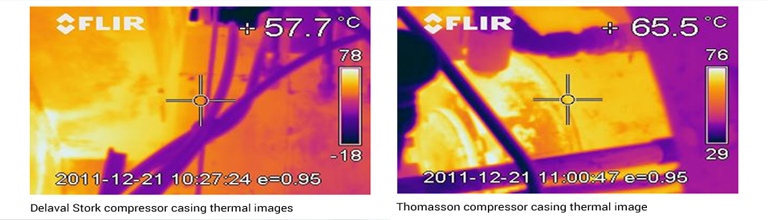

Infrared can locate loose and deteriorated connections in a fraction of the time without tearing down or rebuilding the equipment. With the results of an infrared inspection in hand before a shutdown, manpower and materials can be planned accordingly and problems fixed efficiently.

Many maintenance departments are being asked to perform more duties with less manpower. Incorporating an infrared program into the “maintenance loop” will enable you to work smarter with fewer resources. More companies are realizing this, which is why infrared is growing so rapidly

We find numerous problems in newly installed equipment due to installation oversights, factory connections, and faulty components.

Each time a piece of equipment is repaired or a new component is brought on-line, thermography is the perfect tool to ensure its proper operation and give you the proper documentation to act upon warranty issues. Such a simple inspection policy will reward your company with tremendous gains in quality and reliability and, therefore profits.

We @ Rototech provide IR thermography imaging services for your plant 24×7, with our specialist engineers.